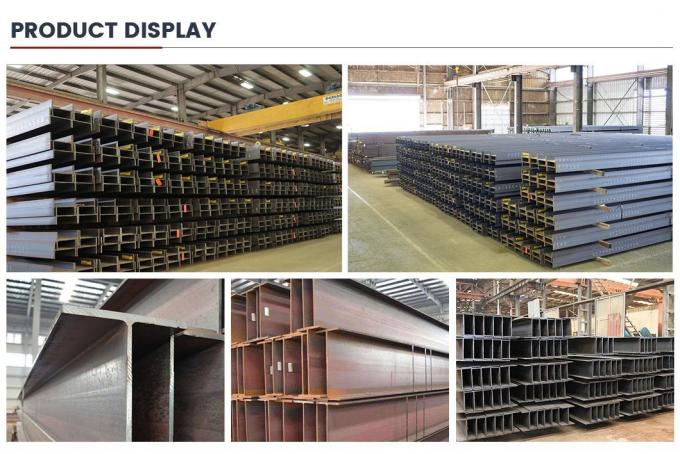

Die Stahlkonstruktion, die hauptsächlich aus warmgewalzten H-Strahlen besteht, hat eine wissenschaftliche und vernünftige Struktur, eine gute Plastizität und Flexibilität, eine hohe strukturelle Stabilität,und für Gebäudestrukturen geeignet, die starken Schwingungen und Aufprallbelastungen standhaltenEs hat eine starke Beständigkeit gegen Naturkatastrophen und eignet sich besonders für Gebäude in erdbebenanfälligen Gebieten.Unter den verheerenden Erdbebenkatastrophen mit einer Stärke von 7 oder mehr in der Welt, Stahlkonstruktionen, die hauptsächlich aus H-Strahlen bestehen, haben den geringsten Schadensgrad.

Die Stahlkonstruktion, die hauptsächlich aus warmgewalzten H-Strahlen besteht, hat eine wissenschaftliche und vernünftige Struktur, eine gute Plastizität und Flexibilität, eine hohe strukturelle Stabilität,und für Gebäudestrukturen geeignet, die starken Schwingungen und Aufprallbelastungen standhaltenEs hat eine starke Beständigkeit gegen Naturkatastrophen und eignet sich besonders für Gebäude in erdbebenanfälligen Gebieten.Unter den verheerenden Erdbebenkatastrophen mit einer Stärke von 7 oder mehr in der Welt, Stahlkonstruktionen, die hauptsächlich aus H-Strahlen bestehen, haben den geringsten Schadensgrad.

| Universalstrahlen | ||||||||||||||||

| Spezifikation:BS EN 10025-2:2004Abmessungen:BS4-1:2005Toleranz:BS EN 10034:1993 | ||||||||||||||||

| Benennung | h | b | s | t | Fläche | IX | Ich | IX | Die | Zx | Zy | |||||

| mmxmmxkg/m | mm | mm | mm | mm | cm2 | cm4 | cm4 | cm | cm | cm3 | cm3 | |||||

| 127x76x13 | 127.0 | 76.0 | 4.0 | 7.6 | 16.5 | 473 | 55.7 | 5.35 | 1.84 | 74.6 | 14.7 | |||||

| 152x89x16 | 152.4 | 88.7 | 4.5 | 7.7 | 20.3 | 834 | 89.8 | 6.41 | 2.10 | 110 | 20.2 | |||||

| 178x102x19 | 177.8 | 101.2 | 4.8 | 7.9 | 24.3 | 1,356 | 137 | 7.48 | 2.37 | 153 | 27.0 | |||||

| 203x102x23 | 203.2 | 101.8 | 5.4 | 9.3 | 29.4 | 2,105 | 164 | 8.46 | 2.36 | 207 | 32.2 | |||||

| 203x133x25 | 203.2 | 133.2 | 5.7 | 7.8 | 32.0 | 2,340 | 308 | 8.56 | 3.10 | 230 | 46.0 | |||||

| 203x133x30 | 206.8 | 133.9 | 6.4 | 9.6 | 38.2 | 2,896 | 385 | 8.71 | 3.17 | 280 | 57.5 | |||||

| 254x102x22 | 254.0 | 101.6 | 5.7 | 6.8 | 28.0 | 2,841 | 119 | 10.10 | 2.06 | 224 | 23.5 | |||||

| 254x102x25 | 257.2 | 101.9 | 6.0 | 8.4 | 32.0 | 3,415 | 149 | 10.30 | 2.15 | 266 | 29.0 | |||||

| 254x102x28 | 260.4 | 102.2 | 6.3 | 10.0 | 36.1 | 4,005 | 179 | 10.50 | 2.22 | 308 | 35.0 | |||||

| 254x146x31 | 251.4 | 146.1 | 6.0 | 8.6 | 39.7 | 4,413 | 448 | 10.55 | 3.36 | 351 | 61.0 | |||||

| 254x146x37 | 256.0 | 146.4 | 6.3 | 10.9 | 47.2 | 5,537 | 571 | 10.80 | 3.48 | 433 | 78.0 | |||||

| 254x146x43 | 259.6 | 147.3 | 7.2 | 12.7 | 54.8 | 6,544 | 677 | 10.90 | 3.52 | 504 | 92.0 | |||||

| 305x102x25 | 305.1 | 101.6 | 5.8 | 7.0 | 31.6 | 4,455 | 123 | 11.87 | 1.97 | 292 | 24.2 | |||||

| 305x102x28 | 308.7 | 101.8 | 6.0 | 8.8 | 35.9 | 5,366 | 155 | 12.23 | 2.08 | 348 | 30.5 | |||||

| 305x102x33 | 312.7 | 102.4 | 6.6 | 10.8 | 41.8 | 6,501 | 194 | 12.47 | 2.15 | 416 | 37.9 | |||||

| 305x127x37 | 304.4 | 123.4 | 7.1 | 10.7 | 47.2 | 7,171 | 336 | 12.30 | 2.67 | 471 | 54.5 | |||||

| 305x127x42 | 307.2 | 124.3 | 8.0 | 12.1 | 53.4 | 8,196 | 389 | 12.40 | 2.70 | 534 | 62.6 | |||||

| 305x127x48 | 311.0 | 125.3 | 9.0 | 14.0 | 61.2 | 9,575 | 461 | 12.50 | 2.74 | 616 | 73.6 | |||||

| 305x165x40 | 303.4 | 165.0 | 6.0 | 10.2 | 51.3 | 8,503 | 764 | 12.90 | 3.86 | 560 | 93.0 | |||||

| 305x165x46 | 306.6 | 165.7 | 6.7 | 11.8 | 58.7 | 9,899 | 896 | 13.00 | 3.90 | 646 | 108 | |||||

| 305x165x54 | 310.4 | 166.9 | 7.9 | 13.7 | 68.8 | 11,700 | 1063 | 13.00 | 3.93 | 754 | 127 | |||||

| 356x127x33 | 349.0 | 125.4 | 6.0 | 8.5 | 42.1 | 8,249 | 280 | 14.00 | 2.58 | 473 | 45.0 | |||||

| 356x127x39 | 353.4 | 126.0 | 6.6 | 10.7 | 49.8 | 10,172 | 358 | 14.30 | 2.68 | 576 | 57.0 | |||||

| 356x171x45 | 351.4 | 171.1 | 7.0 | 9.7 | 57.3 | 12,070 | 811 | 14.50 | 3.76 | 687 | 95.0 | |||||

| 356x171x51 | 355.0 | 171.5 | 7.4 | 11.5 | 64.9 | 14,140 | 968 | 14.80 | 3.86 | 796 | 113 | |||||

| 356x171x57 | 358.0 | 172.2 | 8.1 | 13.0 | 72.6 | 16,040 | 1108 | 14.90 | 3.91 | 896 | 129 | |||||

| 356x171x67 | 363.4 | 173.2 | 9.1 | 15.7 | 85.5 | 19,460 | 1362 | 15.10 | 3.99 | 1,071 | 157 | |||||

| 406x140x39 | 398.0 | 141.8 | 6.4 | 8.6 | 49.7 | 12,508 | 410 | 15.90 | 2.87 | 629 | 58.0 | |||||

| 406x140x46 | 403.2 | 142.2 | 6.8 | 11.2 | 58.6 | 15,685 | 538 | 16.40 | 3.03 | 778 | 76.0 | |||||

| 406x178x54 | 402.6 | 177.7 | 7.7 | 10.9 | 69.0 | 18,720 | 1021 | 16.50 | 3.85 | 930 | 115 | |||||

| 406x178x60 | 406.4 | 177.9 | 7.9 | 12.8 | 76.5 | 21,600 | 1203 | 16.80 | 3.97 | 1,063 | 135 | |||||

| 406x178x67 | 409.4 | 178.8 | 8.8 | 14.3 | 85.5 | 24,330 | 1365 | 16.90 | 3.99 | 1,189 | 153 | |||||

| 406x178x74 | 412.8 | 179.5 | 9.5 | 16.0 | 94.5 | 27,310 | 1545 | 17.00 | 4.04 | 1,323 | 172 | |||||

| 457x152x52 | 449.8 | 152.4 | 7.6 | 10.9 | 66.6 | 21,370 | 645 | 17.90 | 3.11 | 950 | 85.0 | |||||

| 457x152x60 | 454.6 | 152.9 | 8.1 | 13.3 | 76.2 | 25,500 | 795 | 18.30 | 3.23 | 1,122 | 104 | |||||

| 457x152x67 | 458.0 | 153.8 | 9.0 | 15.0 | 85.6 | 28,930 | 913 | 18.40 | 3.27 | 1,263 | 119 | |||||

| 457x152x74 | 462.0 | 154.4 | 9.6 | 17.0 | 94.5 | 32,670 | 1047 | 18.60 | 3.33 | 1,414 | 136 | |||||

| 457x152x82 | 465.8 | 155.3 | 10.5 | 18.9 | 104.5 | 36,590 | 1185 | 18.70 | 3.37 | 1,571 | 152.5 | |||||

| Jumbo-Strahlen | ||||||||||||||||

| Spezifikation:BS EN 10025-2:2004Abmessungen:ASTM A6-11Toleranz:BS EN 10034:1993 | ||||||||||||||||

| Benennung | h | b | s | t | Fläche | IX | Ich | IX | Die | Zx | Zy | |||||

| mmxmmxkg/m | mm | mm | mm | mm | cm2 | cm4 | cm4 | cm | cm | cm3 | cm3 | |||||

| 1016x305x222 | 970.3 | 300.0 | 16.0 | 21.1 | 282 | 406,500 | 9,501 | 37.95 | 5.80 | 8,380 | 633 | |||||

| 1016x305x249 | 980.0 | 300.0 | 16.5 | 26.0 | 317 | 481,100 | 11,750 | 38.97 | 6.09 | 9,818 | 784 | |||||

| 1016x305x272 | 990.1 | 300.0 | 16.5 | 31.0 | 347 | 553,800 | 14,000 | 39.96 | 6.35 | 11,190 | 934 | |||||

| 1016x305x314 | 1000.0 | 300.0 | 19.1 | 35.9 | 400 | 644,700 | 16,280 | 40.15 | 6.38 | 12,890 | 1085 | |||||

| 1016x305x349 | 1008.1 | 302.0 | 21.1 | 40.0 | 444 | 722,300 | 18,460 | 40.32 | 6.45 | 14,330 | 1222 | |||||

| 1016x305x393 | 1016.0 | 303.0 | 24.4 | 43.9 | 500 | 807,700 | 20,500 | 40.18 | 6.40 | 15,900 | 1353 | |||||

| 1016x305x415 | 1020.0 | 304.0 | 26.0 | 46.0 | 529 | 853,100 | 21,710 | 40.17 | 6.41 | 16,728 | 1428 | |||||

| 1016 x 305 x 438 | 1026.0 | 305.0 | 27.0 | 49.0 | 557 | 909,800 | 23,360 | 40.41 | 6.47 | 17,740 | 1532 | |||||

| 1016x305x494 | 1036.0 | 309.0 | 31.0 | 54.0 | 629 | 1,028,000 | 26,820 | 40.42 | 6.53 | 19,845 | 1736 | |||||

| 1016x305x584 | 1056.0 | 314.0 | 36.0 | 64.0 | 744 | 1,246,100 | 33,430 | 40.93 | 6.70 | 23,600 | 2130 | |||||

| Japanische I-Abschnitte (konische Flansche) | ||||||||||||||||

| Spezifikation:BS EN 10025-2:2004Abmessungen:JIS G3192:2008Toleranz:JIS G3912:2008 | ||||||||||||||||

| Benennung | h | b | s | t | Fläche | IX | Ich | IX | Die | Zx | Zy | |||||

| mmxmmxkg/m | mm | mm | mm | mm | cm2 | cm4 | cm4 | cm | cm | cm3 | cm3 | |||||

| 150 mal 75 mal 17.1 | 150 | 75 | 5.5 | 9.5 | 21.83 | 819 | 57.5 | 6.12 | 1.62 | 109 | 15.3 | |||||

| 200 mal 100 mal 26.0 | 200 | 100 | 7 | 10 | 33.06 | 2,170 | 138 | 8.11 | 2.05 | 217 | 27.7 | |||||

| Japanische H-Abschnitte | ||||||||||||||||

| Spezifikation:BS EN 10025-2:2004Abmessungen:JIS G3192:2008Toleranz:JIS G3912:2008 | ||||||||||||||||

| Benennung | h | b | s | t | Fläche | IX | Ich | IX | Die | Zx | Zy | |||||

| mmxmmxkg/m | mm | mm | mm | mm | cm2 | cm4 | cm4 | cm | cm | cm3 | cm3 | |||||

| 100 mal 100 mal 16.9 | 100 | 100 | 6 | 8 | 21.59 | 378 | 134 | 4.18 | 2.49 | 75.6 | 26.7 | |||||

| 125 mal 125 mal 23.6 | 125 | 125 | 6.5 | 9 | 30.00 | 839 | 293 | 5.29 | 3.13 | 134 | 46.9 | |||||

| 150 mal 75 mal 14.0 | 150 | 75 | 5 | 7 | 17.85 | 666 | 49.5 | 6.11 | 1.66 | 88.8 | 13.2 | |||||

| 175 mal 90 mal 18.0 | 175 | 90 | 5 | 8 | 22.90 | 1,210 | 97.5 | 7.26 | 2.06 | 138 | 21.7 | |||||

| 200 mal 100 mal 17.8 | 198 | 99 | 4.5 | 7 | 22.69 | 1,540 | 113 | 8.25 | 2.24 | 156 | 22.9 | |||||

| 200 mal 100 mal 20.9 | 200 | 100 | 5.5 | 8 | 26.67 | 1,810 | 134 | 8.23 | 2.24 | 181 | 26.7 | |||||

| 250 mal 125 mal 25.1 | 248 | 124 | 5 | 8 | 31.99 | 3,450 | 255 | 10.4 | 2.82 | 278 | 41.1 | |||||

| 250 mal 125 mal 29.0 | 250 | 125 | 6 | 9 | 36.97 | 3,960 | 294 | 10.4 | 2.82 | 317 | 47.0 | |||||

Shandong Zhengde Metal Manufacturing Co., Ltd.ist ein Produktions- und Vertriebsunternehmen, das warmgewalzte Stahlspulen, kaltgewalzte Stahlspulen, galvanisierte Stahlspulen, farblich beschichtete Stahlspulen, Abschnittsstahl, Stahlrohre, Stahldrähte, Metallnetze integriert,aus rostfreiem StahlIn den Niederlanden, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japanmit mehr als 100 Produktionslinien, 4 national anerkannte Laboratorien, 2 technische Ingenieurzentren und 5 Unternehmenstechnologiezentren. Die Produkte werden in mehr als 50 Länder und Regionen wie Nordamerika,Südamerika, Europa, Afrika, Ozeanien, Naher Osten und Südostasien.

Shandong Zhengde Metal Manufacturing Co., Ltd.ist ein Produktions- und Vertriebsunternehmen, das warmgewalzte Stahlspulen, kaltgewalzte Stahlspulen, galvanisierte Stahlspulen, farblich beschichtete Stahlspulen, Abschnittsstahl, Stahlrohre, Stahldrähte, Metallnetze integriert,aus rostfreiem StahlIn den Niederlanden, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japan, Japanmit mehr als 100 Produktionslinien, 4 national anerkannte Laboratorien, 2 technische Ingenieurzentren und 5 Unternehmenstechnologiezentren. Die Produkte werden in mehr als 50 Länder und Regionen wie Nordamerika,Südamerika, Europa, Afrika, Ozeanien, Naher Osten und Südostasien.